Taking care of your control valves requires routine maintenance and servicing. In fact, every part of each type of valve in your applications requires its own customized maintenance plan. Sometimes this maintenance should happen daily, and sometimes it should be part of a preventive maintenance program or part of a larger-scale plant turnaround; how frequently your valve needs maintenance will depend on the severity of service and how critical the application is.

Here are five control valve tips every maintenance planner should know about:

- Valve packing needs to be visually inspected for leaks on a regular basis.

- To maintain your air set or supply regulator, you should blow down moisture and impurities as needed on a daily, weekly, or quarterly basis. You should also inspect or replace your filter media and diaphragm on a regular basis.

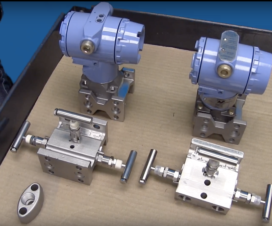

- Whether you have an I/P transducer or valve positioner, routine maintenance is necessary. Check the valve stroke and calibrate the I/P transducer or valve positioner on a quarterly or semi-annual basis.

- Your actuator doesn’t require frequent maintenance – once a year, or as appropriate, inspect the diaphragms, piston rings, and end seals. You should also lubricate.

- Valve trim also requires infrequent maintenance. Inspect the trim and replace elastomer trim components and metal seats on a yearly basis.

Use these five tips to help you create a customized maintenance plan to fit your needs. By keeping your valves maintained and operating well between turnarounds, you will be able to protect your plant from unplanned, costly, and lengthy interruptions.

If you have questions or need a valve quote, contact us today.