Manifolds are used when you need to isolate your process connection. It sounds simple enough, but given the wide variety of manifolds available, the subject of “manifolds” can be confusing.

To help clear up some questions, we’ll lay out some of the different kinds of manifolds as well as some common applications.

Let’s start by talking valves. Generally, manifolds are sold with a particular number of valves based on the required operation. Here are the most common assemblies with example applications and use cases:

- 2-valve manifold

- Application: gauge pressure transmitters

- Use case: isolates the transmitter and vents the pressure off

- 3-valve manifold

- Application: differential pressure transmitters

- Use cases: blocks each process connection; equalizes two sensor diaphragms

- 5-valve manifold

- Application: differential setups

- Use case: blocks, equalizes, and vents two process connections

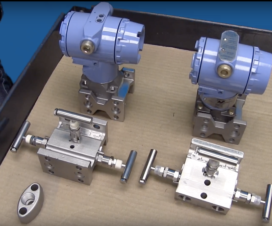

And below are some of the different styles of manifolds:

- Integral manifold

-

- Mounts directly to a pressure transmitter with no process flange

- Subtypes

- Traditional: process connection comes in from the side of the manifold

- Coplanar: process connection comes in from the bottom of the manifold

- Conventional manifold

-

- Mounts to the side of a process flange (as opposed to mounting directly on the pressure transmitter’s sensor)

- Used when you prefer to leave a manifold piped in-line

- Allows removal of the pressure transmitter for maintenance or replacement

- Process connection styles

- ½” NPT

- “Football” connections (also called “process adapters”)

- In-line (also called “block and bleed”) manifold

-

- Used on “direct-connect” style transmitters

- Generally 2-valve, ½” NPT combinations involving female and male connections

Still have questions? Don’t hesitate to reach out to us at (314) 665-1741.