In the market for a 3051 pressure transmitter?

These transmitters are incredibly versatile. In fact, 3051s can be configured in hundreds of different ways. So before you start shopping, familiarize yourself with these five questions. The answers will help you determine the right instrument for your application.

What process would you like to automate?

The first thing you need to ask yourself is, “What process am I trying to automate?”

Below are a couple of examples.

Example #1 — Triggering a release valve

For this example, we’ll use pulp and paper. As pulp flows through your lines, pressure rises to potentially dangerous levels. In this case, you may want a pressure transmitter to sense high pressure and subsequently send out an electronic signal that triggers a relief valve to open.

Example #2 — Recording measurements

3051s are also commonly used to record pressure measurements. With the readings, you can determine why pressure changes, and with that understanding, optimize your manufacturing process.

What are you trying to measure?

A common answer is gauge pressure, which is a single measurement that will tell you what the pressure is inside of a pipe. You can also use a transmitter to measure differentials, the difference between two pressures, or absolute pressure, which measures pressure below zero. Rosemount 3051s can also be used to measure fluid levels.

What do you know about your process fluid?

Your process fluid and all of its properties have an enormous bearing on what transmitter and calibration is right for your application.

First, what is your process fluid? If it’s water, chances are you can use stainless steel material. But if you’re transporting harsh ingredients, you might need a more durable material such as tantalum or hastelloy.

Temperature is another critical consideration. Suppose that your process fluid gets very hot. If your process fluid reaches a certain level on the temperature curve, based on the density of your process fluid, you may require a different calibration or sensor range.

Will you measure fluid levels with your transmitter? In that case, you’ll need to determine specifications about your process including tank level height, elevated or suppressed zero, and specific gravity of your process and fill fluid.

What is your pressure range or level range?

Determining a specific pressure or level range will ensure you get accurate measurements from your transmitter.

Think of it this way. Imagine measuring out just one centimeter. Would you rather use a six-inch ruler or a yardstick?

For instance, a 100 psi measuring sensor with a full-range calibration will measure anywhere from 0-100 psi. If you only need to measure up to 50 psi, the 100 psi measuring sensor isn’t necessarily your best option. Why? Full-range calibrations can put you at a disadvantage regarding accuracy.

To further illustrate, say you only need to measure 0-20 psi. With the 100 psi sensor, you’d only use one-fifth of your full measurement span. You would be better off using a sensor that measures from 0-30 psi. With this smaller range, you’d be using two-thirds of your measurement span as opposed to one-fifth, which means your readings will be more accurate.

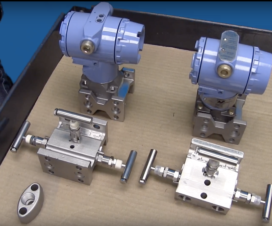

What process connection do you need?

The process connection depends on a variety of factors including your process fluid, if you’re setting up a remote or local pressure measurement, and details on your pipe threading. National pipe thread (NPT) connections, sanitary tri-clamp, and flanged connections are just a few examples of process connections.

The type of application you’re measuring will help you determine your ideal process connection. Say you need a remote seal. In this situation, your process connection will differ from a standard instrument connection — you might need an extended flanged seal or recessed flanged seal.

Another situation is using a wet leg, where you’re running a pipe up the side of your tank. Then you may need two different types of process connections on the same instrument.

—

If you’re unsure of the answers to some of these questions, there’s no need to worry. Contact us to speak with an engineer who can help set you up with a transmitter that will get the job done.

Get started today by calling Valves Depot at (877) 544-4897.