Like any other piece of equipment in your facility, control valves — and all of their components — require regular maintenance.

Using these five tips, you can make a custom maintenance plan that will keep your processes running smoothly between turnarounds.

Tip #1: Inspect valve packing for leaks

How often: frequently

Your valve packing can start leaking at any time, so it’s essential to inspect the packing regularly. If you catch a leak soon enough, you can usually fix it by tightening and resealing the packing.

A couple more suggestions:

- Every 1-2 years, consider a complete replacement.

- Occasionally, you’ll need to inspect the packing box walls.

Tip #2: Blow down moisture and impurities

How often: daily, weekly, or quarterly

Blowing down moisture and impurities will help maintain your air set (or supply regulator). You should do this as needed on a daily, weekly, or quarterly basis.

Also, make sure to inspect or replace your filter media diaphragm every year. In some cases, you can make these replacements less frequently.

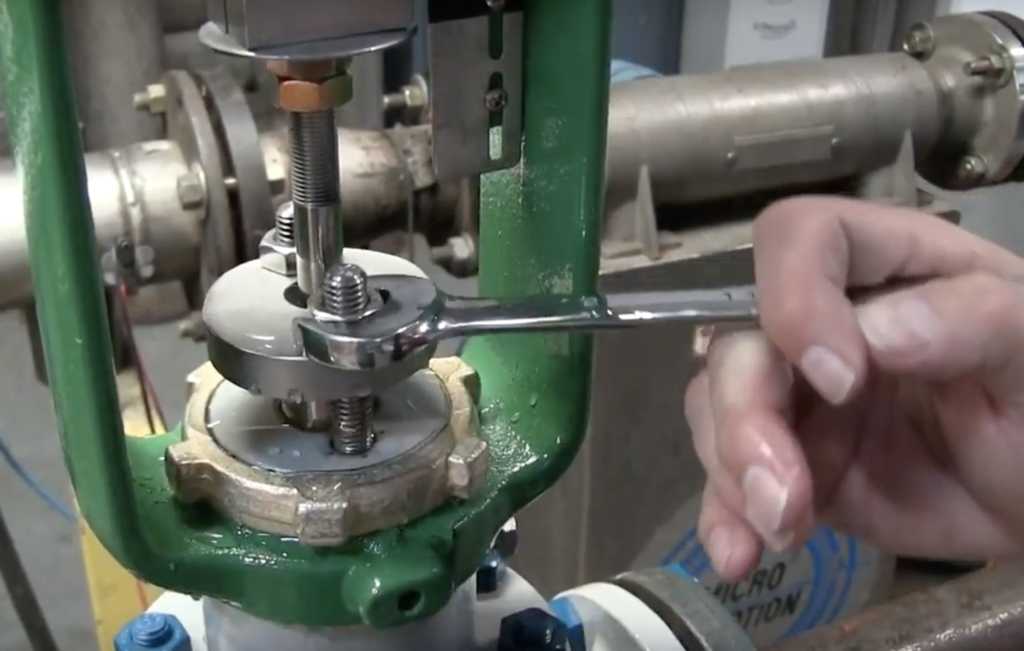

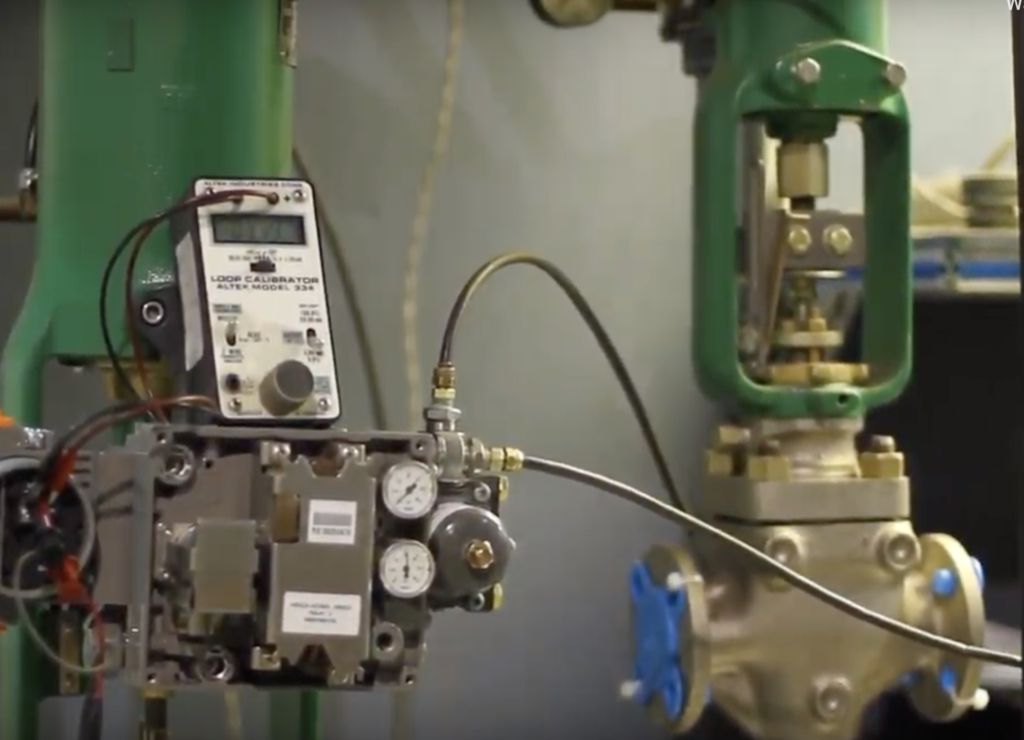

Tip #3: Check the valve stroke and calibrate transducers and positioners

How often: quarterly, semi-annually, or annually, depending on your processes

Depending on the process, you’ll need to regularly check valve stroke and calibrate your Eye to Pee transducers or valve positioners.

If you have a critical process, do this on a quarterly or semi-annual basis. With less critical processes, you can put this task on the calendar every year or so.

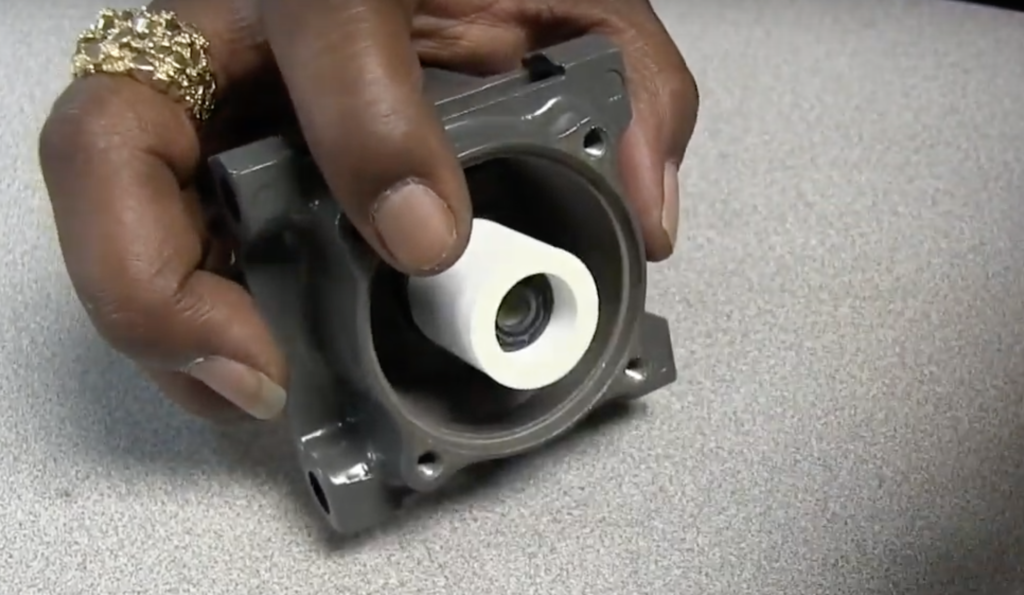

Tip #4: Examine actuator components

How often: annually

Actuators don’t require frequent maintenance, but they do deserve a little TLC. Each year, take a look at the diaphragms, piston rings, and end seals to make sure they’re still in good shape. While you’re doing that, lubricate piston type actuator cylinders and O-rings.

Tip #5: Check on valve trim

How often: annually or less frequently, depending on your processes

If you have critical processes, conduct an annual visual inspection to ensure your valve trim is in good condition. At the same time, replace elastometer trim components and metal seats. With less critical processes, you can inspect valve trim less frequently or replace the trim on an as-needed basis.

Watch the video here:

—

Call Valves Depot at (314) 597-9749 today for a custom quote on premium remanufactured control valves.