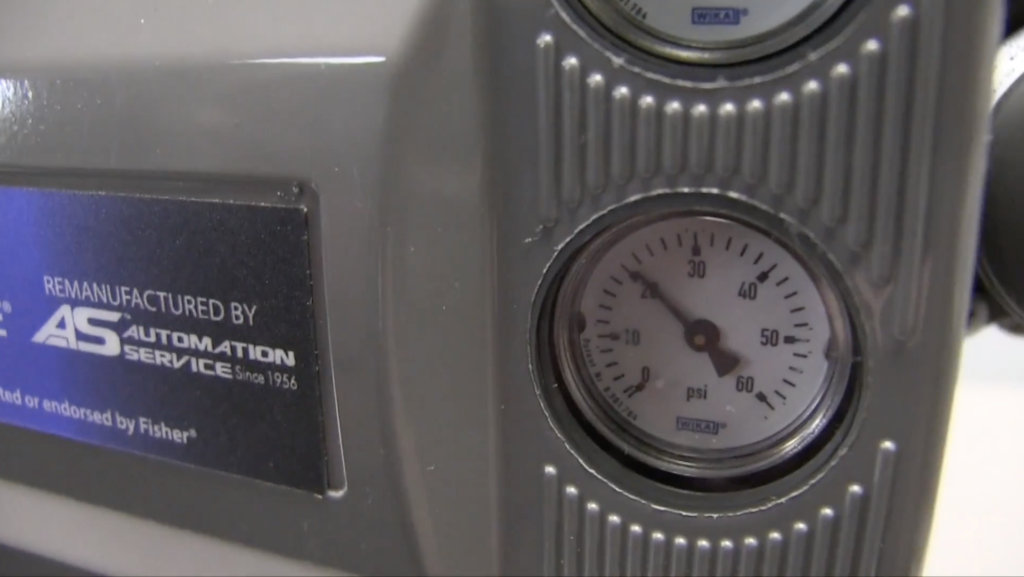

Air filter regulators: do you really need them?

Technically, no, you don’t. However, using air filter regulators with your pneumatically actuated valves can increase the lifespan of your devices.

Purchasing an air filter regulator is a small investment, but a worthy one. Here’s why.

Air filter regulators:

- Provide the instrument with a supply of stable air pressure

- Prevent actuators from over-pressuring (over-pressuring can lead to instrument malfunctions)

- Prevent water and debris from entering small air passages within the instrument

Quick maintenance tips

Using an air filter regulator with your valves has plenty of benefits. But your new equipment will require some maintenance. To get you started, here are a couple of quick tips.

Tip #1: Drain water in the drip well

It’s a common misconception that instrument air supply systems deliver clean, dry air. In fact, poor air quality is the leading cause of premature instrument failure. You can prevent device failure by periodically draining any water that accumulates in the drip well. The process is simple. Open the drain valve, allow any water to drain out, and close the valve again.

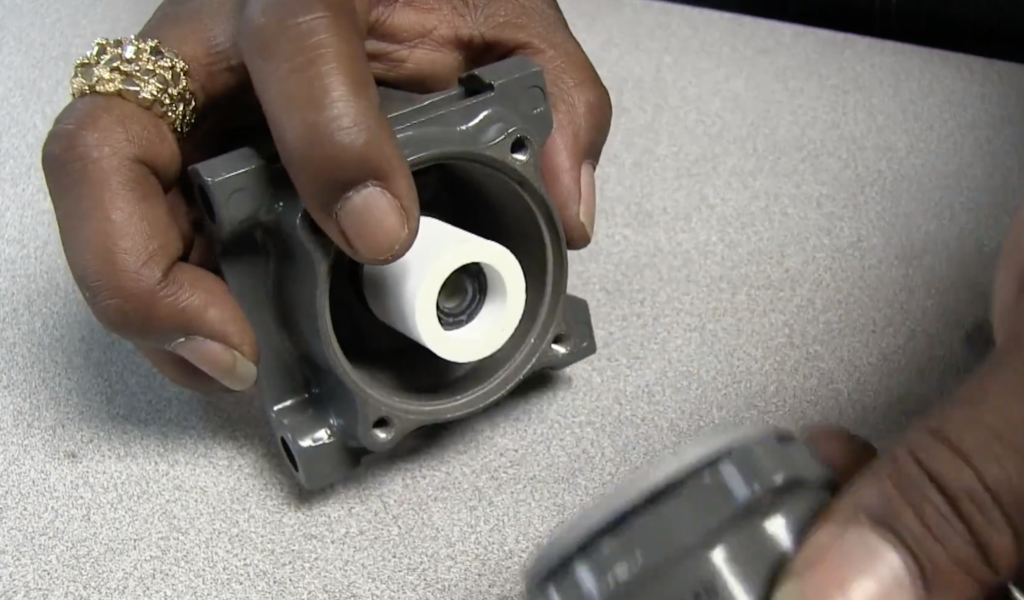

Tip #2: Check the filters

Every time you perform routine maintenance or calibrate your instrument, take a look at the filter. If it’s in poor condition, replace it — in the long run, this will save you time and money!

Watch the video:

—

Call Valves Depot at (314) 597-9749 today for a custom quote on premium remanufactured control valves.