Here are some of the most commonly asked questions that our valve experts get from customers.

Selection FAQs

How much do pressure relief valves cost?

It depends. Some of the valves we carry run between $100-$200, as they are suitable for smaller applications. Some industrial settings may need larger or more robust valves, which can run upwards of $1,000 or $2,000.

What information do I need to size and select a valve?

Properly sizing and selecting a pressure relief valve requires several pieces of information, including:

- Connection size and type

- Set pressure (psig)

- Temperature

- Back pressure

- Service

- Required capacity

Does weather and temperature affect valve performance?

It can. You should consider any extreme temperatures and environmental and working conditions when you’re selecting a valve. For example:

- High ambient temperatures can affect the set pressure of the valve

- Low ambient temperatures combined with moisture can make valves freeze which could lead to possible malfunction

More information: How To Specify Kunkle Safety and Pressure Relief Valves

Set Pressure FAQs

How do I determine what set pressure I need?

Here are two possible ways to make this determination.

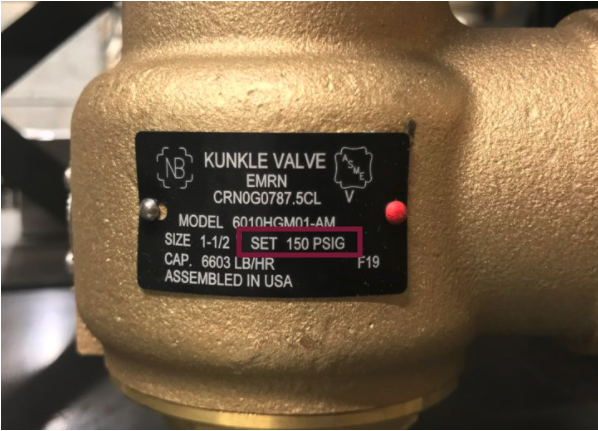

- If you’re replacing a valve, refer to the nameplate.

Kunkle valve nameplate with a set pressure of 150 psig

2. If you’re purchasing a valve for a new application, you may be able to make this determination based on a few guidelines.

- Your valve’s set pressure should never exceed the maximum allowable working pressure (MAWP) of the vessel that the valve is protecting.

- We recommend that your maximum expected operating pressure will not exceed 90% of the valve’s set pressure. This helps to ensure the valve’s seat will stay tight.

- Identifying the process media, or service, of a valve is important to set pressure. If a valve has the correct set pressure but is used on the wrong application, there’s a chance the valve won’t open when needed. This could cause an overpressure event.

Can I swap a valve to another unit if the set pressure is the same, but the service is different?

Sometimes.

- You cannot use a Section VIII coded valve for any Section I application.

- You can use a Section I coded steam valve on Section VIII steam applications.

If the valve design allows, you may be able to reset a Section VIII coded valve for other media within Section VIII.

Does altitude affect set pressure?

No. The valve’s set pressure is measured in gauge pressure, or pounds per square inch gauge (psig), so you don’t have to take altitude into account when selecting your valve.

How does back pressure affect a valve’s set pressure and capacity?

Back pressure can have complex effects on a valve’s set pressure, capacity, and overall performance. If you know your application will have any type of back pressure, we recommend getting in touch with one of our specialists to verify how it may affect your valve selection or performance.

ASME Code FAQs

What are ASME Sections I, IV, and VIII?

When you’re shopping on Valves Depot or looking at a valve nameplate, you might see references to ASME Sections I (V stamp), IV (HV stamp), or VIII (UV stamp) in the valve specs. These refer to the ASME (American Society of Mechanical Engineers) Boiler and Pressure Vessel Code (BPVC) standard, a set of guidelines for valve manufacturing.

Each section lays out valve manufacturing guidelines based on application:

- Section I covers fired pressure vessels, usually a boiler.

- Section IV covers low pressure steam boilers and hot water heating boilers.

- Section VIII covers unfired pressure vessels, or anything that isn’t a boiler.

If you are referring to your valve nameplate and don’t see an ASME stamp, don’t worry — there are a couple of reasons this might happen.

- Some valves are non-coded by design. For example, some liquid applications and vacuum services don’t require ASME certified valves.

- If your relief valve has a set pressure below 15 psig, it won’t have an ASME stamp.

Installation FAQs

What mounting orientation should be used to install a safety valve?

You should install your valve vertically. This will help to ensure that:

- The valve body is self-draining.

- The valve is installed to code.

- The correct seat tightness and set pressure will be achieved.

Installing a safety valve in any position other than with the spindle vertical and upright may adversely affect performance and lifetime.

Are there any recommendations for my inlet piping?

Yes. Your inlet piping should:

- Be as short as possible

- Have no elbows

- Have a diameter equal to or greater than the valve inlet connection

It’s important to make sure that the inlet pressure drop is < 3% when the valve relieves pressure.

Are there any recommendations for my outlet/discharge piping?

Yes. Your valve should be connected to piping that:

- Never contains pressure before the valve opens

- Has pressure build-up less than 10% of the valve’s set pressure when the valve is opening and relieving

- Is independently hung and supported

- Has a drip pan elbow or flexible connection between the valve and the pipe (steam service only)

What can I do to make sure I don’t damage my valve during installation?

When you’re installing a smaller valve, preventing damage is as simple as handling the new valve with care. Some parts are fragile. But for larger, heavier valves, during installation, pay close attention to the lever — make sure your lifting straps don’t accidentally wrap around or otherwise conflict with it.

For information on installing Kunkle valves, check out this article.

Can I paint my valve?

Never paint or otherwise cover any working or internal valve parts.

Maintenance FAQs

How often should I test and inspect my valve?

We recommend performing inspections and tests on your valves regularly — doing so could help extend the life of your valve.

- After you install a new valve, perform an initial visual inspection no longer than 12 months into operation.

- After your initial inspection, schedule maintenance every two to six months. Your maintenance interval will depend on your service conditions and the age of the valve.

What should I check during a visual inspection?

During a visual inspection, check for:

- Clogged drains and discharge pipes

- Dirt buildup around the seat

- Broken, damaged, or missing parts and seals

Read more: Extend the Life of Your Kunkle Valve With Regular Maintenance

Troubleshooting FAQs

Why is there a hole in the valve body?

Some valve models are required to have a drain hole per the ASME Boiler and Pressure Vessel Code. The drain hole helps prevent condensate from accumulating in the body that could freeze or corrode internal valve parts.

Why is my valve leaking?

Leaks can be caused by a number of things, including:

- System operating pressure is too close to set pressure

- Dirty or damaged seats

- Valve damage

- The valve not closing all the way

Just because your valve is leaking doesn’t necessarily mean that you need a new valve or repairs — you may need to adjust your operating procedures. Lowering your system pressure, accounting for expected pressure spikes, and regularly calibrating your gauges are a few possible ways to help stop or prevent leakage.

Why should I order valves from Valves Depot?

We keep a vast inventory of valves in stock, so we can generally ship valves within three business days. Plus, most orders qualify for free shipping.